Loading a PCB typically involves three different areas with different methods of component preparation and different placement techniques.

PCB's designed for production are generally cheaper to manufacture than boards requiring excessive manual intervention. If unsure about production ready PCBs then please contact us for general advice.

PCB Loading Methods

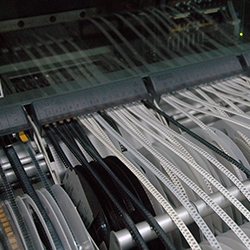

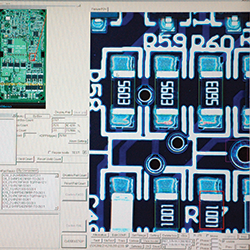

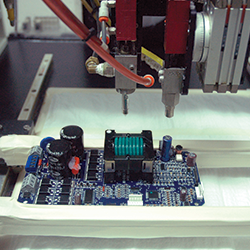

- Surface Mount placement is the most common design used today. This involves placing reels of components on a Pick and Place Machine and configuring that machine to place the component in its designated spot.

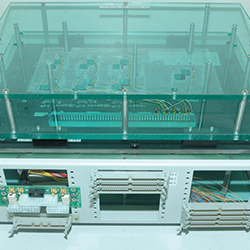

- Through Hole placement generally involves the pre-preparation of the component for insertion into the PCB. Typical preparation involves lead forming and bending the component.

- Finally there is the Custom Component. Today components are becoming varied and complex, with specialized placement techniques. These components generally require manufacturer's special instructions for placement.

Soldering Methods

- Surface Mount components are placed onto solder paste deposited on the PCB and then sent though an oven with an individual soldering profile.

- Through Hole components are typically soldered on a wave soldering machine but are also hand soldered if they are in a difficult position on the PCB.

- Custom components may use either of the above techniques or be press-fitted or use some other special technique.